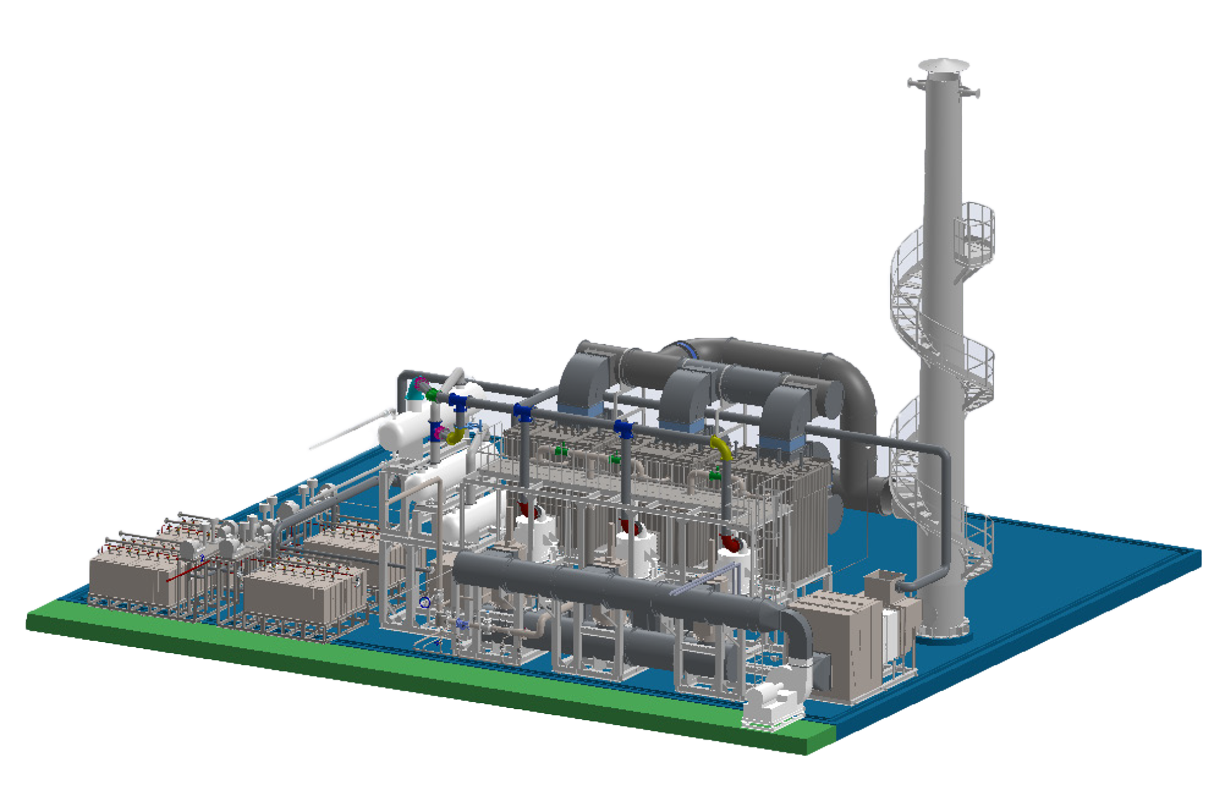

Gas recovery unit

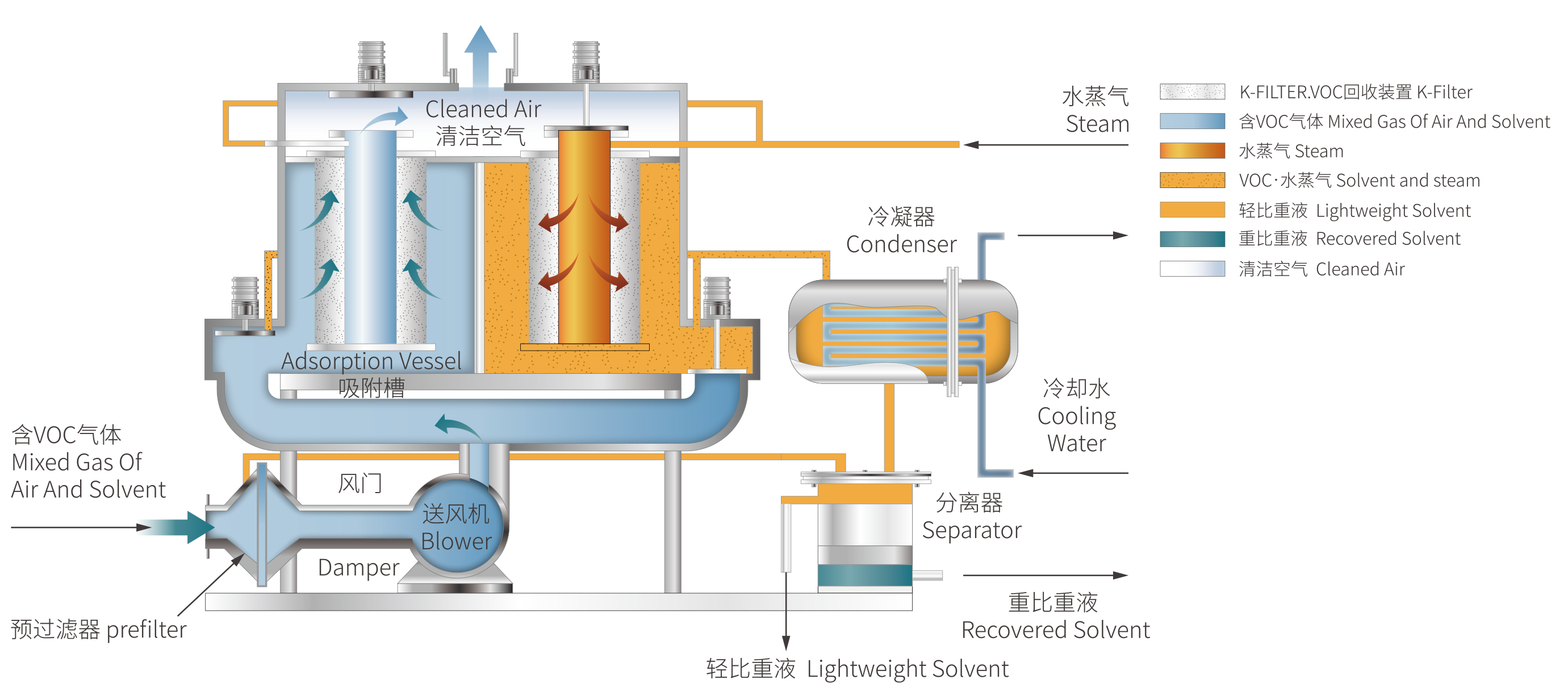

Relying on the world's best activated carbon fiber filter element and adopting the adsorption-desorption-condensation recovery process, we can achieve the recovery of high-quality organic solvents and ensure that the exhaust gas meets the emission standards.

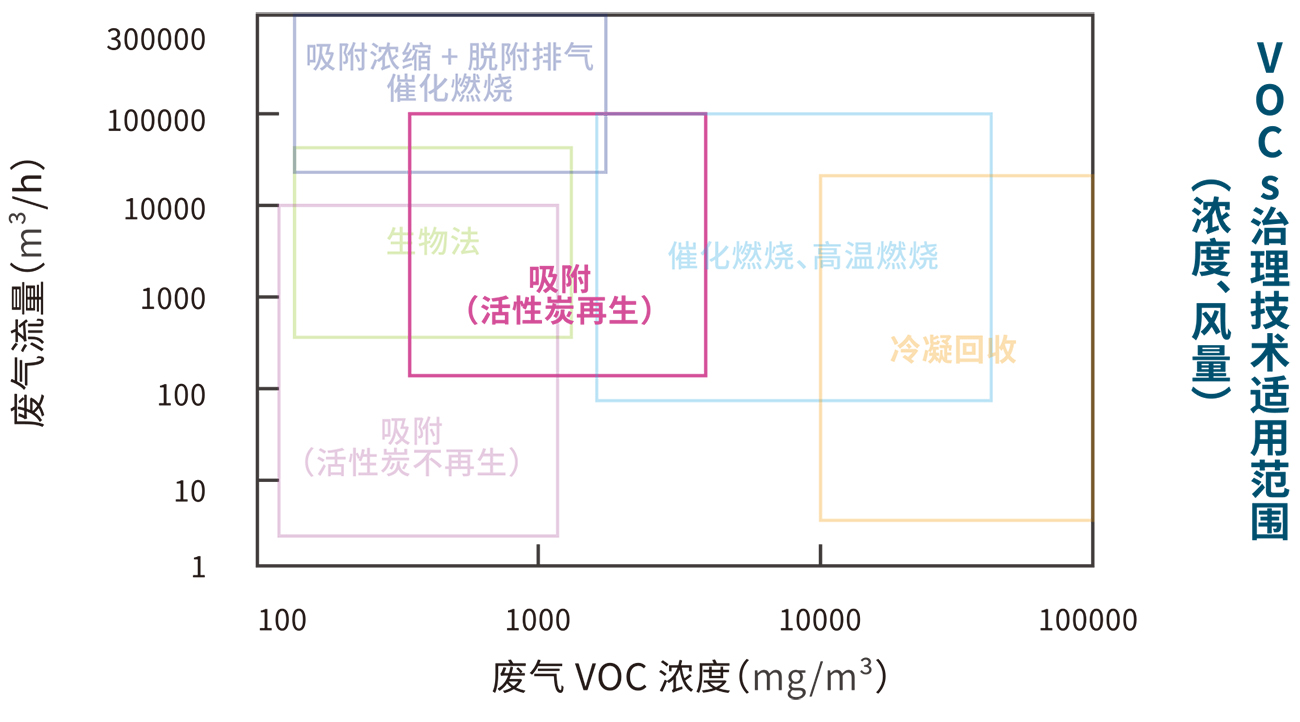

Technology application range

Our activated carbon fiber gas recovery device is suitable for VOCs recovery and treatment with air volume of 100-100000m³/h and concentration of 500-6000mg/m³.

Applicable organic matter

Hydrocarbons: benzene, toluene, xylene, n-ethane, naphtha, protective film volatile oil, cyclohexane, methylcyclohexane, dioxane, diluent, gasoline, etc.

Halogenated hydrocarbons: trichloroethylene, perchloroethylene, dioxyethane, chloroform, trichlorobenzene, chloroform, carbon tetrachloride, freons, etc.

Ketones: acetone, MEK (methyl ethyl ketone), MIBK (methyl isobutyl [methyl] ketone), cyclohexanone, etc.

Ethers: formaldehyde, acetic acid, methylacetic acid, THF (tetrahydrofuran), methyl cellosolve, etc.

Alcohol ethers: methanol, ethanol, isopropanol, butanol, formaldehyde, acetaldehyde, furfural, etc.

Others: vinyl chloride, acrylic acid, vinyl acetate, etc.

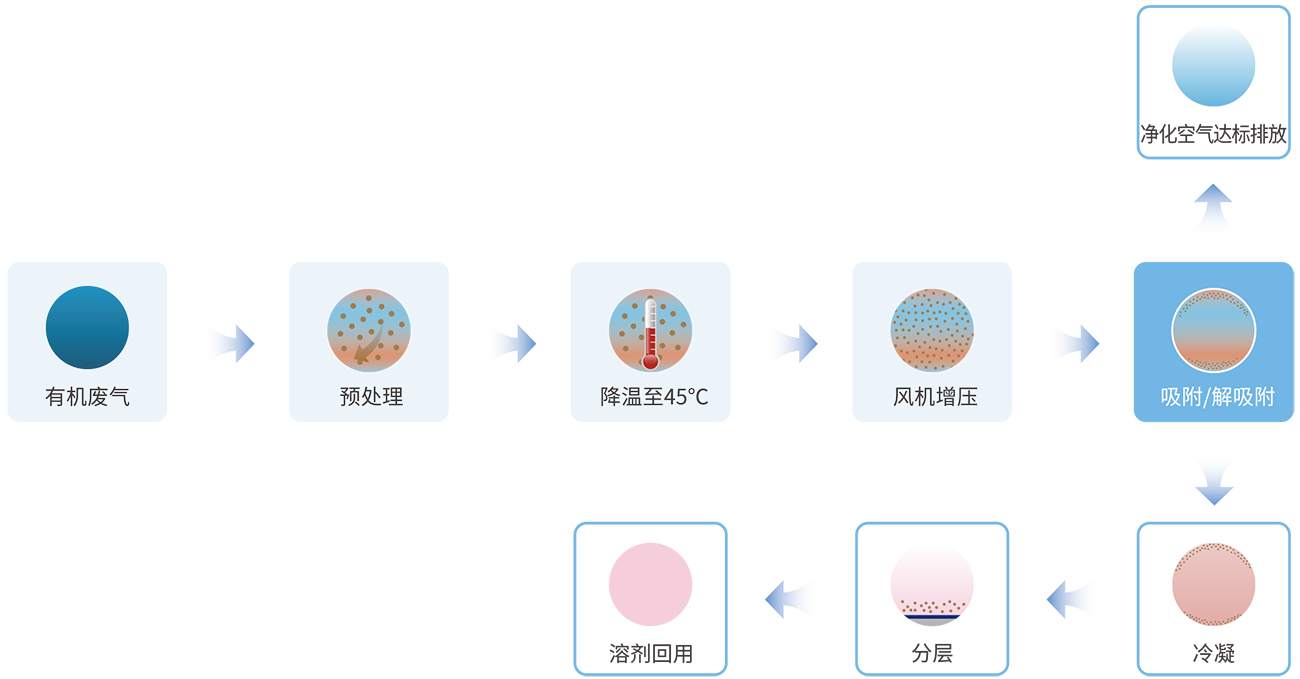

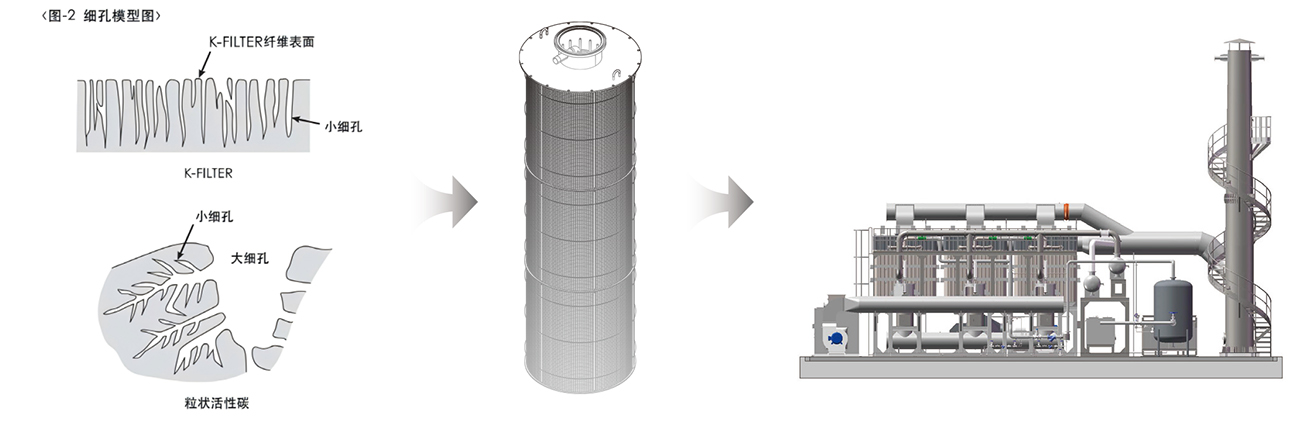

Process diagram

Equipment Features

High-efficiency adsorption performance: Made of high-quality activated carbon fiber material, it has a very high specific surface area and unique microporous structure, which can quickly adsorb harmful substances in the gas.

Rapid desorption and regeneration:

Through our unique desorption technology, the regeneration of adsorption materials can be completed in a short time, greatly improving production efficiency and equipment life.

Environmental protection and energy saving:

The desorption process has low energy consumption, which reduces the impact on the environment and reduces operating costs.

Widely used:

It is suitable for a variety of gas treatment occasions, including but not limited to industrial waste gas treatment, indoor air purification, harmful gas recovery, etc.