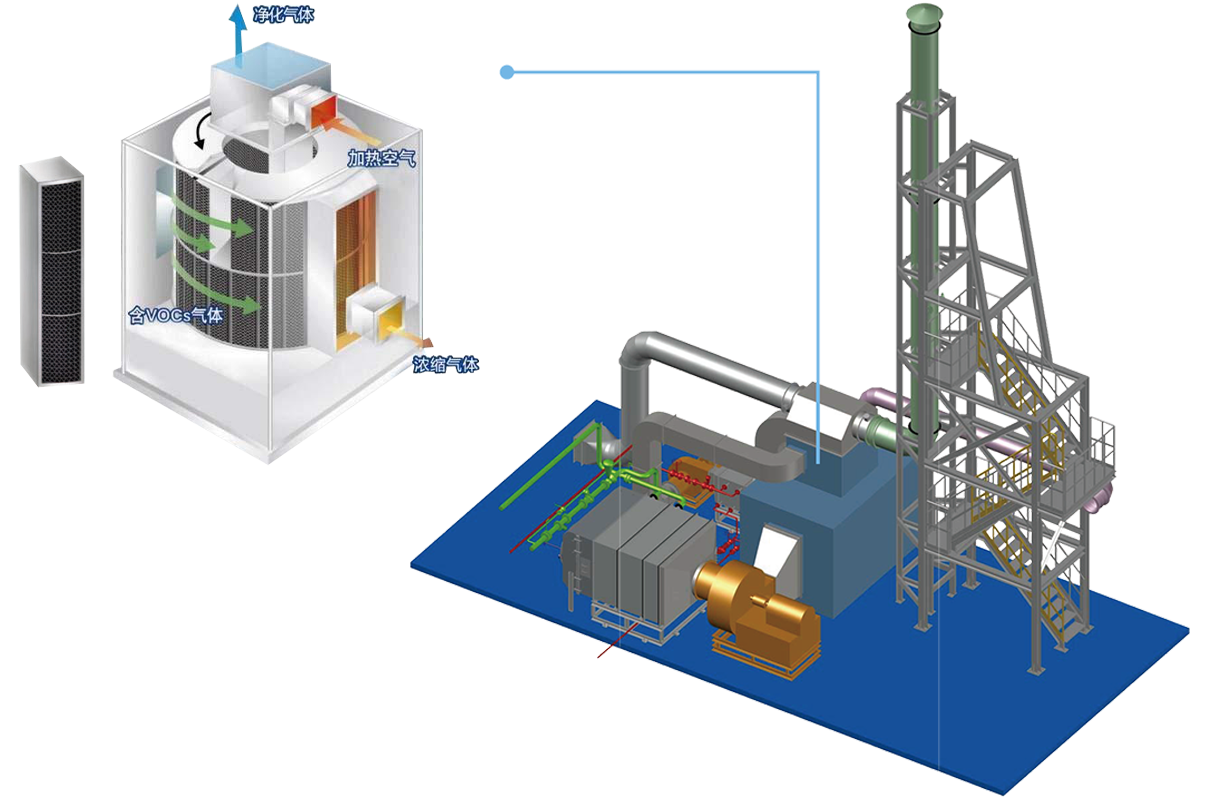

Rotary recovery device

Relying on internationally professional activated carbon fiber modules, the adsorption-desorption process is used to concentrate low-concentration exhaust gas into high-concentration exhaust gas. In conjunction with the gas recovery device, high-quality organic solvent recovery can be achieved. The purified gas reaches the country's most stringent concentration of 20mg/m³ before being discharged into the atmosphere.

Process diagram

Technology application scope

Common volatile organic solvent components with a boiling point of 40-200°C are generally applicable, and there are also some special cases (such as isophorone 206°C). The application fields are wide: equipment coating, rubber industry, coating industry, unorganized exhaust of large workshops, printing waste gas, electronic semiconductors, petrochemical industry, etc. The life of the core components is 4-6 years.

Equipment Features

Using ACF activated carbon fiber as the concentration module has a higher purification efficiency, up to 99%.

The concentration ratio is higher, 5-40 times.

There is no general concentration wheel honeycomb ceramic substrate, lower specific heat capacity, and no cooling partition.

Modular assembly, simple, safe and convenient.

Can be double-layered to improve processing capacity.